System Introduction

Targets

Establish an efficient and rapid excavation system integrating "digging, supporting and transporting" to integrate the traditional distributed processes of digging, transporting and supporting through new technologies and equipment, realize parallel operations of digging and anchoring, simultaneous support by multiple arms, continuous crushing and transportation, long-pressure and short-extraction ventilation and remote intelligent control, and realize truly comprehensive excavation automation.

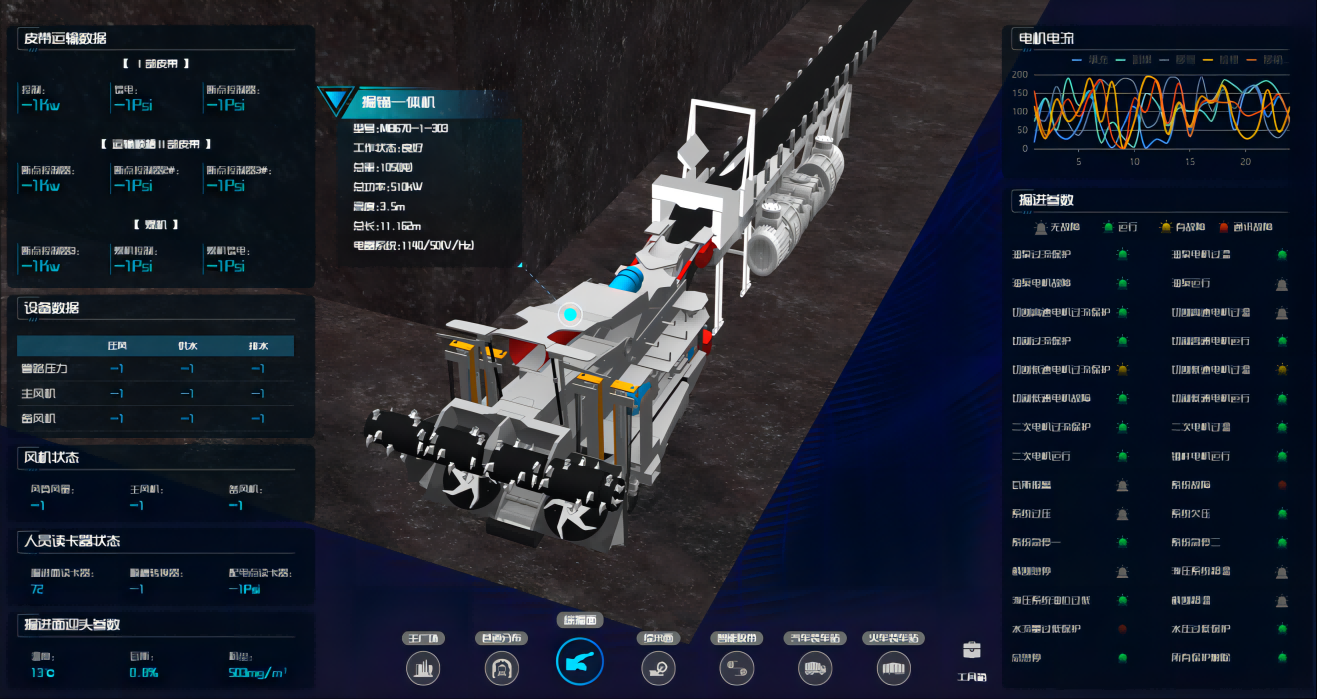

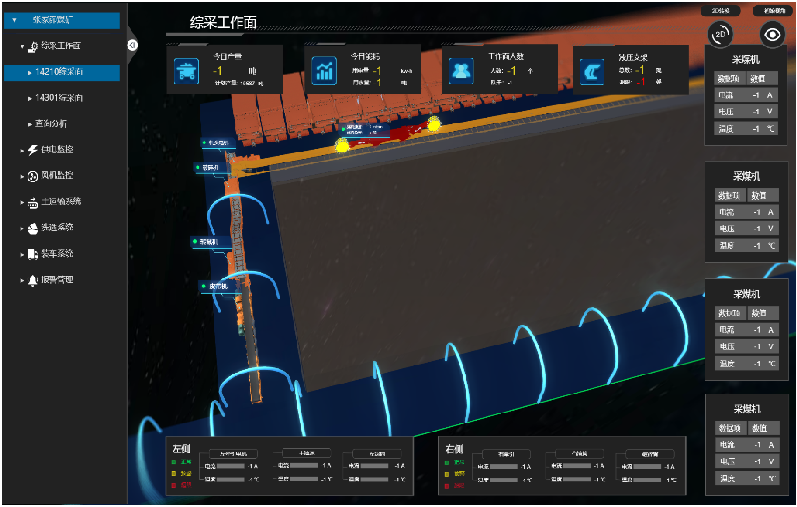

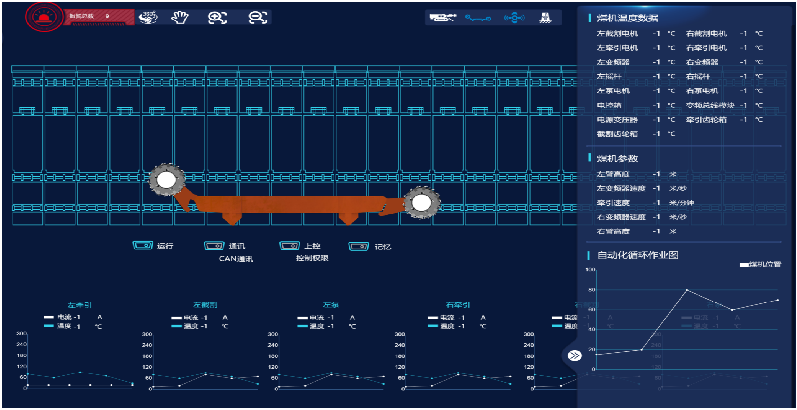

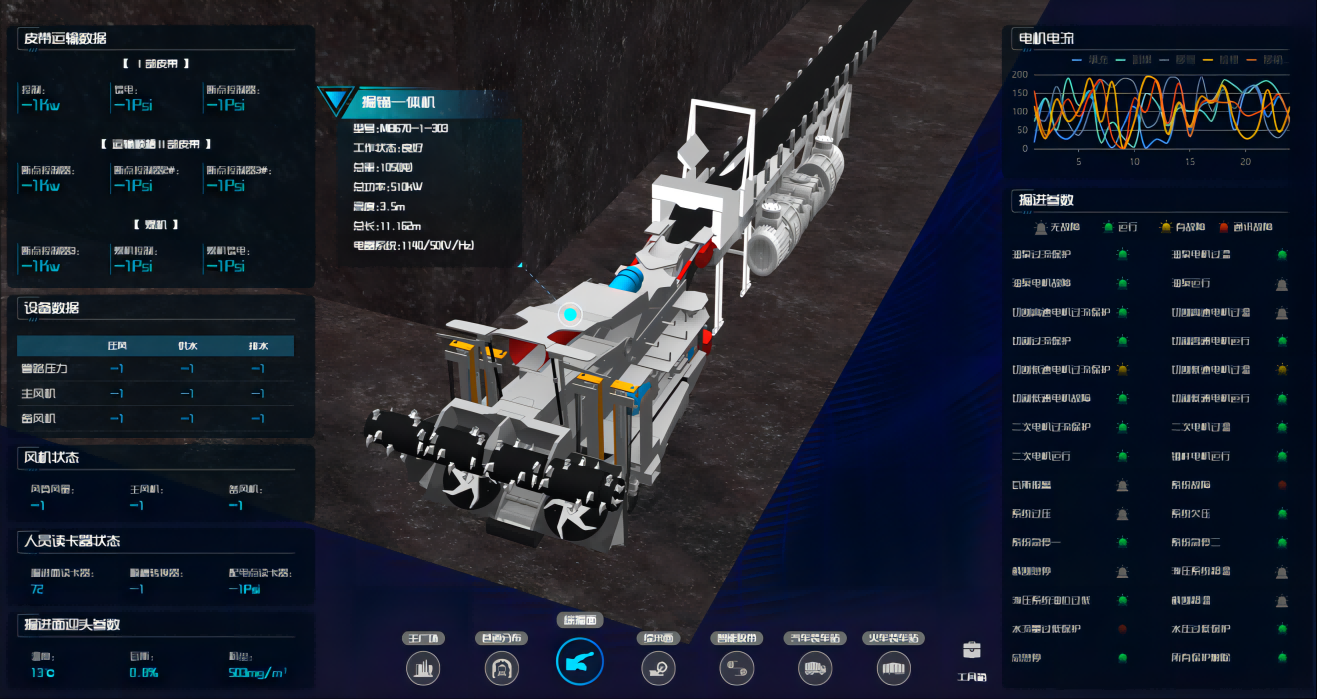

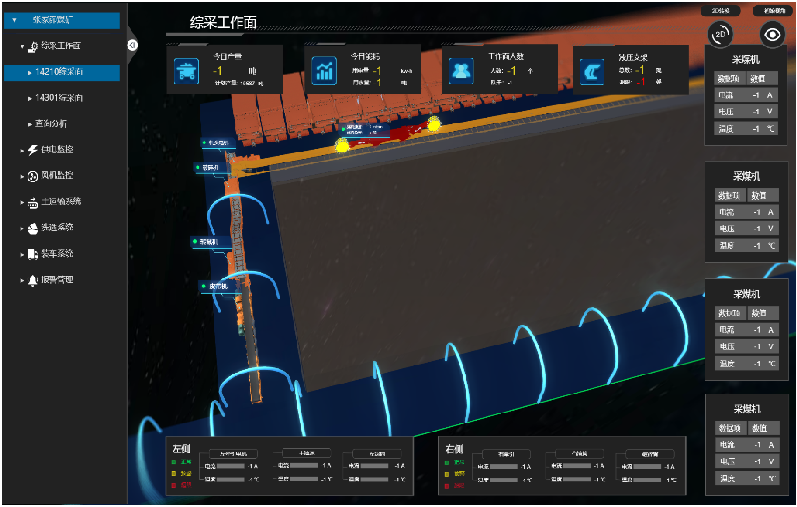

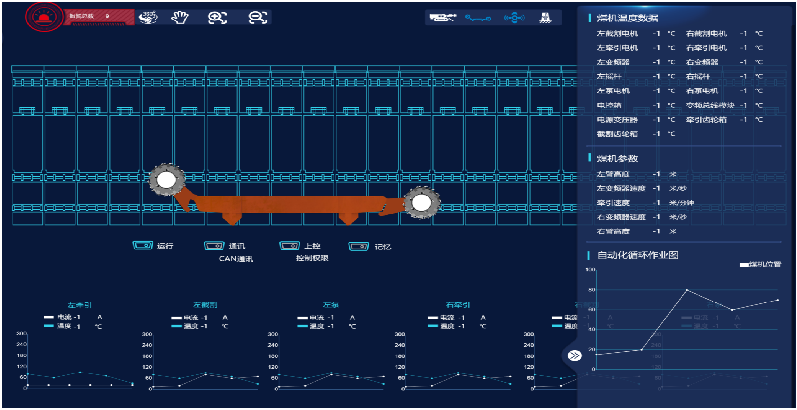

Digital monitoring of excavation working face

1. Collect data and upload them to the underground remote monitoring console and the ground sub-control center to realize the real-time display and control function of the anchor boring machine status.

2. The operating status of the anchor breaking and transporting machine is displayed in real time on the underground remote monitoring console and the ground sub-control center, and the electrical fault self-diagnosis and regular maintenance reminder and information push function are provided.

3. The combined navigation system consists of a laser transmitter, a laser receiving target, an inclination sensor, and a controller to realize the directional navigation of the equipment.

4. The multi-machine collaborative control consists of the existing equipment control system, sensors, control substations, main control stations, and upper monitoring systems. Each part is integrated into a unified underground excavation monitoring system through the network system, and operates stably according to the operation process.

System Function

-

Intelligent perception: Use new generation information technologies such as artificial intelligence, big data, and the Internet of Things to enable intelligent equipment upgrades, perceive the trend of excavation and gas excavation, changes in cutting objects, abnormal conditions of wind speed and air volume, coordination of excavation and transportation processes, operation status of equipment such as excavators and belt conveyors, quality data of drilling holes for water exploration and gas extraction, and human-machine environment data of personnel operations in the production process.

-

Intelligent decision-making: Fusion analysis of engineering design data and intelligent perception data of human-machine environment in the production process, combined with mine operation procedures, to achieve intelligent identification of abnormal conditions, automatic alarm, and intelligent decision-making of equipment linkage control.

-

Automatic alarm: Combined with the labor organization structure and job responsibilities of the mine, the alarm information formed by intelligent decision-making is pushed to the operating personnel and managers at all levels.

-

Linkage control: Based on AI+IOT technology, it is effectively combined with the equipment control system to send the equipment control instructions formed by intelligent decision-making to the excavation working face equipment to achieve linkage control of the equipment, or push the equipment operation prompt information to the operator to assist the operator in remote operation.