1. Product description

With the acceleration of automation and information construction in coal mine production process, the requirements for scientific management of coal mine power supply system have been raised to a new height. Nowadays, with the improvement of coal mining mechanization, the reliability and rationality of coal mine power supply and distribution system operation become more and more important. Relying on the intelligent integrated protection device of the terminal equipment of the Internet of things, it is necessary to establish a set of perfect power monitoring system to ensure the safe operation of the ground and underground power grid, and realize the peak load shifting and valley filling of power supply, which can bring huge social and economic benefits to the coal mine.

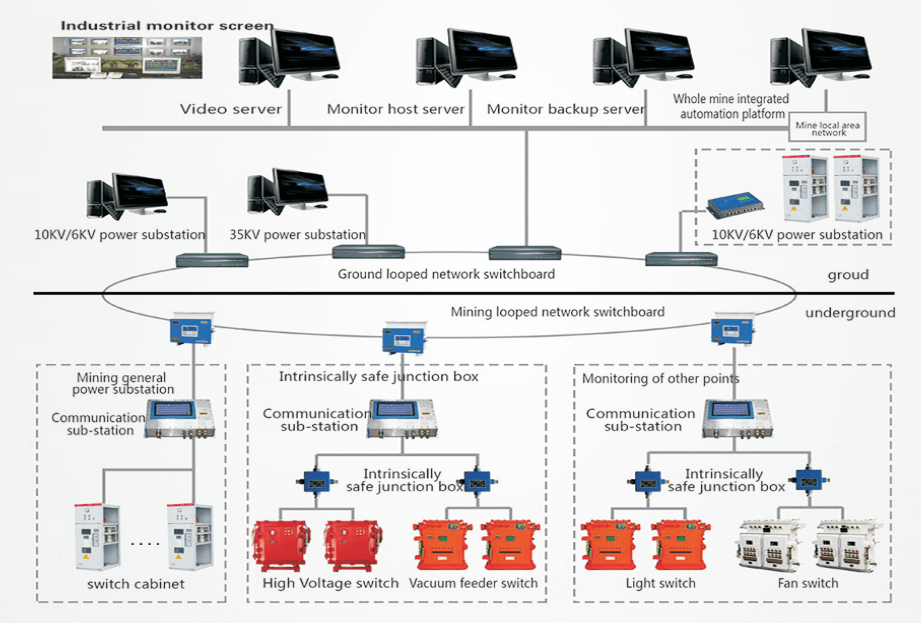

A KJ1062-F power monitoring substation is installed in each substation in the mine, and the WTG-200 type microcomputer integrated protector built in the explosion-proof switch in the substation is connected to the network by RS485 bus. The power monitoring substation is after the information is processed, it is uploaded to the ground system host through the industrial Ethernet ring network that has been built underground in the mine, and through the ground monitoring room background system host to realize remote telemetry, remote control, remote signaling, and remote control of the high voltage switch of the underground substation,tuning and other functions.

The ground power monitoring and dispatching center is equipped with two sets of redundant power monitoring system software, which are respectively installed on the two redundant upper management computers of the ground power monitoring and dispatching center. The ground power monitoring and dispatching center uses the integrated automation system gigabit industrial Ethernet ring network transmission platform that has been built in the mine for data transmission.

2. Product advantage

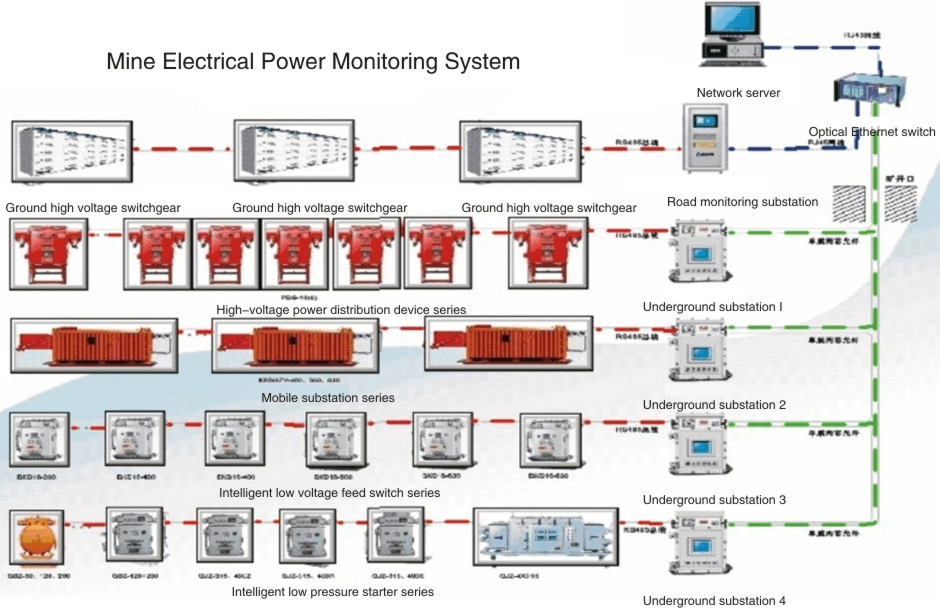

After full demonstration, the mine power monitoring and control system uses Ethernet as the basis to build a communication network, and adopts a hybrid scheme of fieldbus and broadband network. It adopts a two-level hierarchical distributed network structure, substation equipment adopts RS485 field bus, and broadband network between substations. The network structure adopts the star topology structure based on the hub, the broadband layer of the transmission medium is optical fiber, and the field bus layer is the signal cable.

The monitoring system adopts the structure mode of industrial Ethernet plus field bus. The backbone channel is the fiber optic Ethernet ring network that the mine has built. The data of the field equipment is connected to the main transmission system of the backbone ring network through the KJ1062-F power monitoring substation arranged on the site of the substation; RS485 is adopted through the intelligent terminal equipment The field bus method collects the operating status and parameters of the field equipment, realizes the functions of centralized data monitoring and equipment control in the substation, and at the same time processes the collected information and uploads it to the system host of the ground monitoring room through the underground ring network. Centralized monitoring and monitoring of downhole equipment on the ground.

The system information of the monitoring background can be connected to the mine automation system through the OPC interface and published in the local area network through the web.

3. Service characteristics

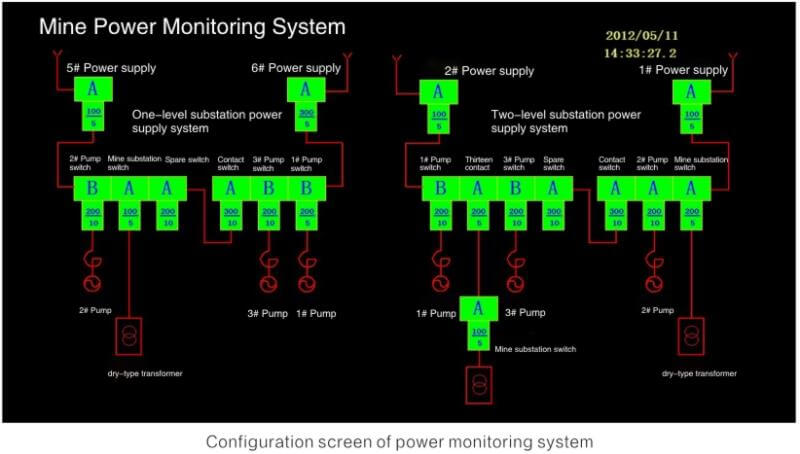

①Data acquisition and processing, real-time acquisition of analog, switch, digital, temperature, pulse, and various event information. Real-time data processing can perform statistics, analysis and calculations on real-time data. For example, by calculating the voltage qualification rate, load rate, power, reactive power, current, total load, power factor, maximum/minimum day/month/year and time and date of occurrence, and the cumulative value of electric energy by time, Digital input state quantity logic operation value, etc.; equipment normal/abnormal displacement times and distinguish, etc. Statistical calculations support rich expression forms.

②The communication network adopts the bus topology structure, and the interface provides communication methods such as Ethernet optical port, Ethernet electrical port, RS485, CAN, RS232, etc. The communication medium adopts twisted pair, optical fiber, etc., and remote communication is realized through the communication interface device.

③There are two ways of alarm processing, one is accident alarm and the other is advance alarm. The former includes circuit breaker tripping and protection device action signals caused by non-operation. The latter includes general equipment displacement, abnormal state information, analog quantity over-limit/re-limit, various components of the computer station control system, abnormal state of the bay unit, etc.

Accident alarm

When an accident occurs, the public accident alarm will immediately sound an audible alarm (the alarm volume is adjustable). The LCD screens of the station control layer and the bay layer use color changes and flashes to indicate the device’s displacement. At the same time, the screen displays a red alarm clause. Print the alarm text, and the remote control terminal device sends the alarm information to the remote control center.

The accident alarm is confirmed manually or automatically. The alarm is confirmed every time, and the automatic confirmation time is adjustable. Once the alarm is confirmed, the sound and flashing stop immediately, the color of the alarm clause changes, and the alarm information is saved.

At the stage of the first accident alarm, if the second alarm occurs, the same process is applied, and the first time is not covered.

The alarm device can be manually tested at any time, and the test information will not be transmitted or recorded.

b.Warning alarm

When an advance warning occurs, the handling method is the same as that of an accident alarm, and the sound and the color of the information provided can be distinguished from the accident alarm. Can selectively send information to remote places.

Tel : +8618355333980

Tel : +840949930668(CDCP)

Email : contact@wantaiglobal.com

Address : Intersection of Guohuai Road and Chunshen Street, Shannan New District, Huainan City, Anhui province, China