Advance detection system during excavation: the "smart eye" of mine excavation

Apr 07, 2025

WANTAI

Advance detection system while digging

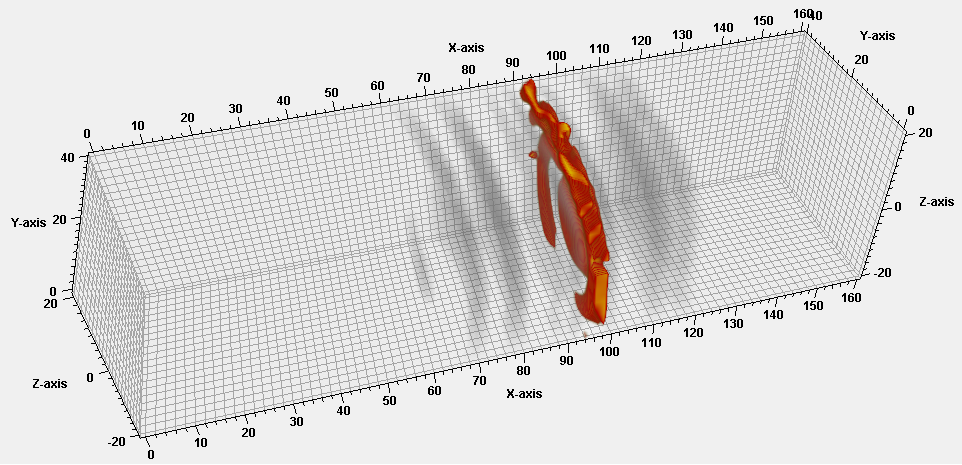

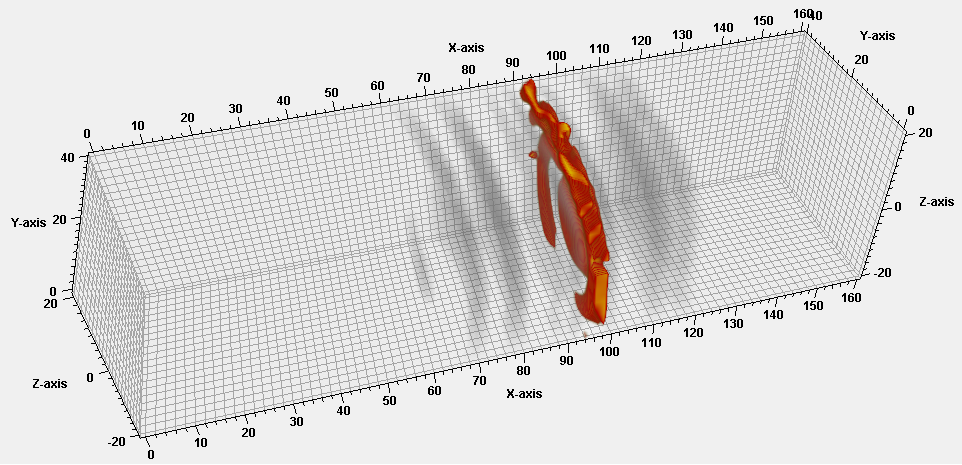

The advance detection technology during excavation uses the domestic advanced scattered wave stacking imaging algorithm. In terms of data processing, this technology extracts scattered wave signals in addition to the conventional cross-correlation processing of each receiving channel and the source channel. More importantly, it utilizes the infinite duration of continuous signals, and based on statistical laws and the repeatability of effective signals, the signal-to-noise ratio of the original seismic data and the accuracy of the inversion results are greatly improved through the principle of multiple stacking. The deep domain diffraction scanning offset stacking imaging technology is used to perform three-dimensional imaging of advance detection during excavation. As shown in the figure.

Three-dimensional view of geological prediction during excavation

PART.01

Limitations of traditional geophysical exploration methods

-

Drilling detection: intuitive, but low construction efficiency, high cost, belongs to single-point detection, and all production activities must be stopped during detection.

-

Electrical detection: advanced detection based on stratum apparent resistivity, but affected by stray currents and operating equipment (tunneling machines), the effective detection distance is limited, and all production activities must be stopped during detection.

-

Seismic detection: using explosives as seismic sources to obtain the location information of geological anomalies in mine tunnels, but all production activities must be stopped, and it is not suitable for high-gas mines (protruding coal seam tunnels).

PART.02

Advantages of advanced detection technology during excavation

-

Realize the detection of unfavorable geological bodies within 150 meters in front of the tunnel, including geological anomalies such as faults, collapse columns, and fissure development zones.

-

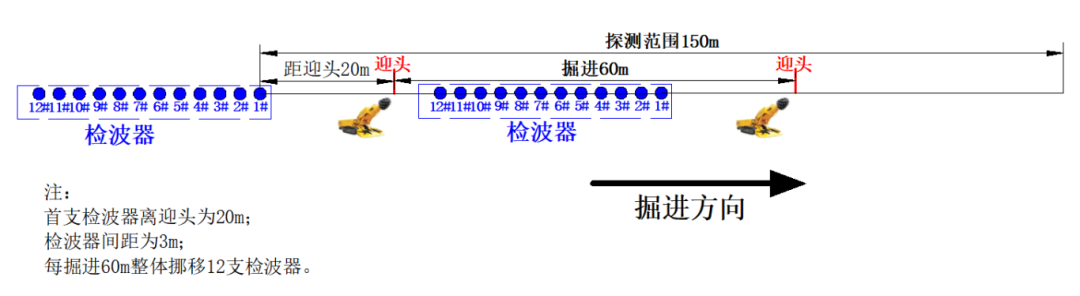

There is no need to stop production for detection. The seismic wave signals generated by the cutting of rock mass by tunneling equipment such as comprehensive excavation machines are used as the source excitation signals for the advance detection during excavation. By laying out array sensors and recording the seismic waveforms during excavation in real time, the deep domain diffraction scanning offset stacking imaging technology is used to perform three-dimensional imaging of the advance detection during excavation.

-

The detection data can be uploaded to the ground server in real time, automatically analyzed to form a report, and dynamic multiple stacking processing can be realized to improve the detection accuracy.

-

The advance detection system during excavation can be connected with the geological support system to provide real-time data for geological modeling, meeting the requirements of intelligent mines and transparent geological construction.

-

Based on the redundancy of the front information provided by the 24-hour continuous acquisition signal, real-time high-precision detection and dynamic geological prediction of the unfavorable geological body in front of the tunnel are realized, providing a geological basis for the safe construction of tunnel excavation, truly minimizing the labor intensity of on-site geophysical exploration, real-time advanced exploration and prediction, realizing advanced intelligent exploration, reducing manpower and improving efficiency, and ensuring excavation safety.

PART.03

Project Cases

-

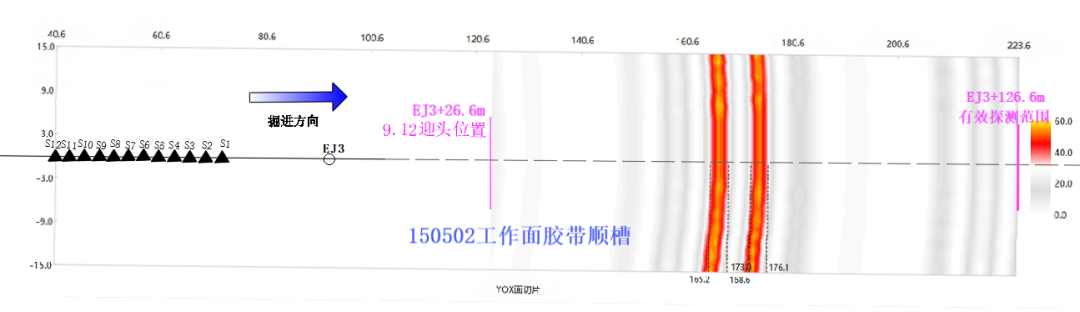

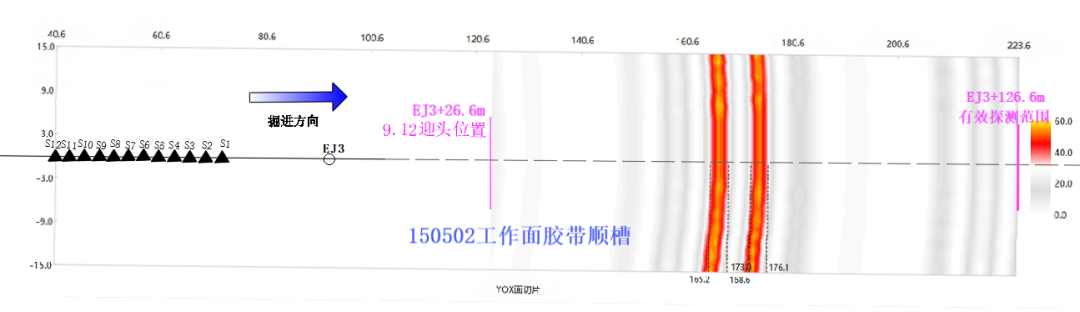

Project Overview: In order to ensure the safety of excavation of the 150502 working face of a coal mine, the excavation advance detection technology was implemented during the excavation of the 150502 belt drift in the 1505 mining area. This method has different technical content and technical requirements from the conventional advance exploration of excavation structures. Based on the relevant interference theory, inversion analysis is performed to accurately calculate the spatial position of the geological structure and achieve advance prediction.

-

Detection results: The EJ3 point is superimposed from 69.4m to 73.4m inward (in the excavation direction) to form an offset high-energy zone. After the tunnel is excavated, a fault (272°∠50°H=1.3m) is exposed from 63.5m to 67.6m in front of the measuring point EJ3.

150502 Excavation face cycle detection schematic diagram

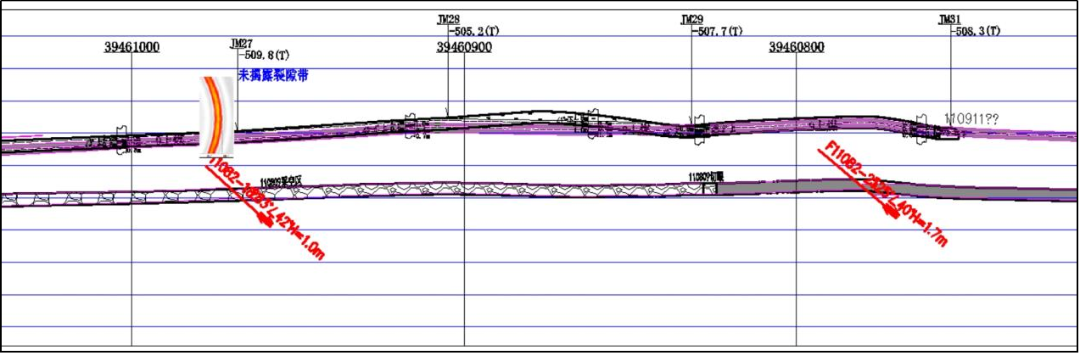

150502 Excavation face detection results map

-

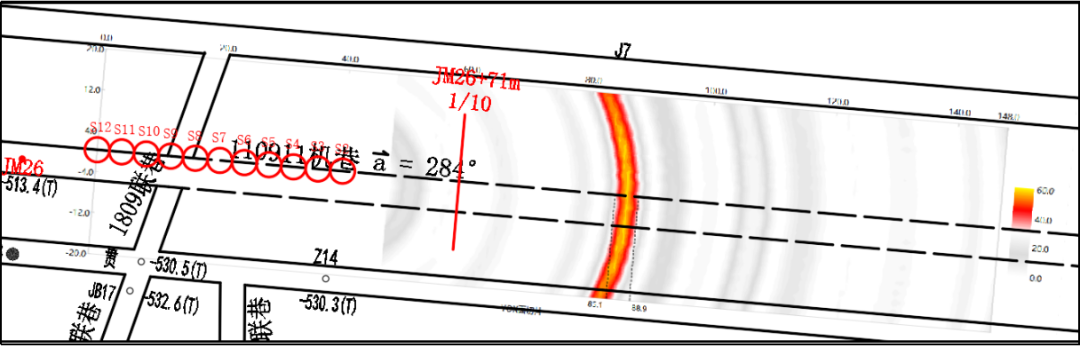

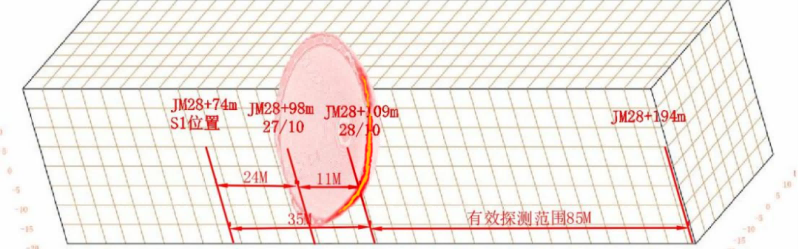

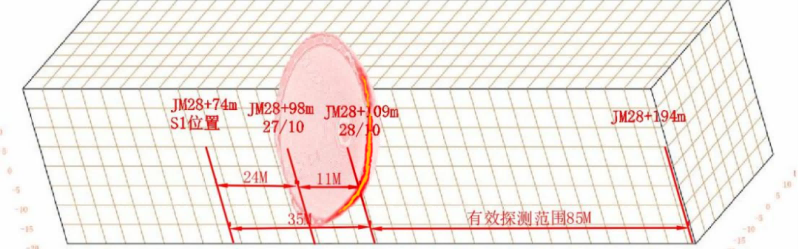

Project Overview: A tunneling advance detection system was built in the 110911 working face machine tunnel to conduct inversion analysis, real-time monitoring and advance prediction of the location of geological structure development.

-

Detection results: The inversion position of the abnormal body is located 105m in front of the measuring point JM28, and the actual location is 103m in front of JM28, with an error of 2m. From the data inversion results, it is preliminarily judged that this place is a fracture development zone. The actual location is that the two sides of the roof within the detection range are relatively broken, and there is a fracture development zone. The reason for the analysis is that the head-on approach to the position of the 8 coal goaf, the internal collapse of the goaf, and the rock movement and stretching have an impact on the front of the 9 coal 110911 working face machine tunnel, resulting in the appearance of anomalies.

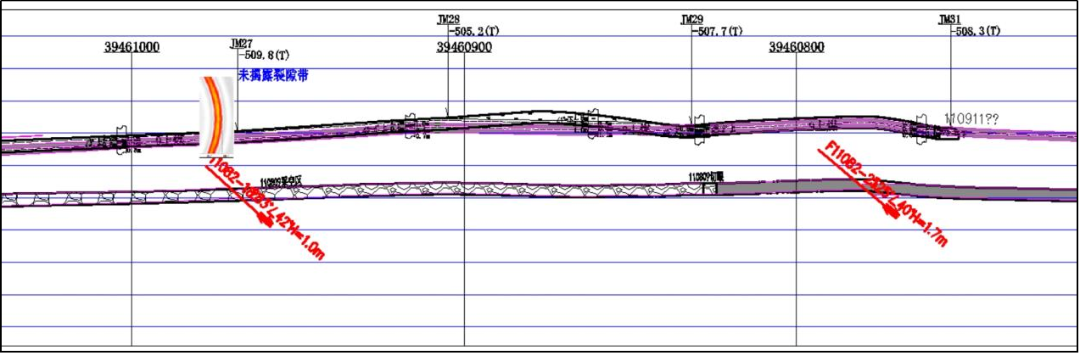

The results of the three inversion analysis of abnormal positions are combined with the tunnel plan

Three real-world geological data of abnormal locations combined with the cross-sectional diagram of the detection results

Detection inversion analysis 3D inversion map