Brand:

WANTAIItem NO.:

STYBOrder(MOQ):

1Payment:

T/T,D/P,etc.Market Price:

30000Price:

$30000/setPrice Range:

1 - 1000Product Origin:

ChinaColor:

WhiteShipping Port:

China portLead Time:

30 days1. Product introduction

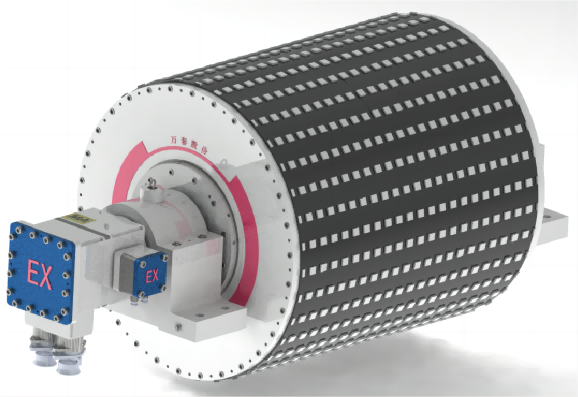

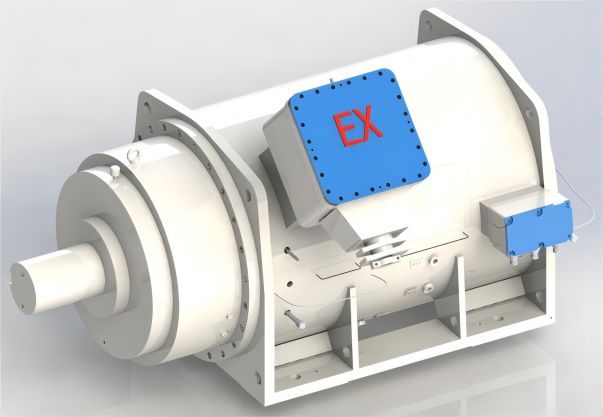

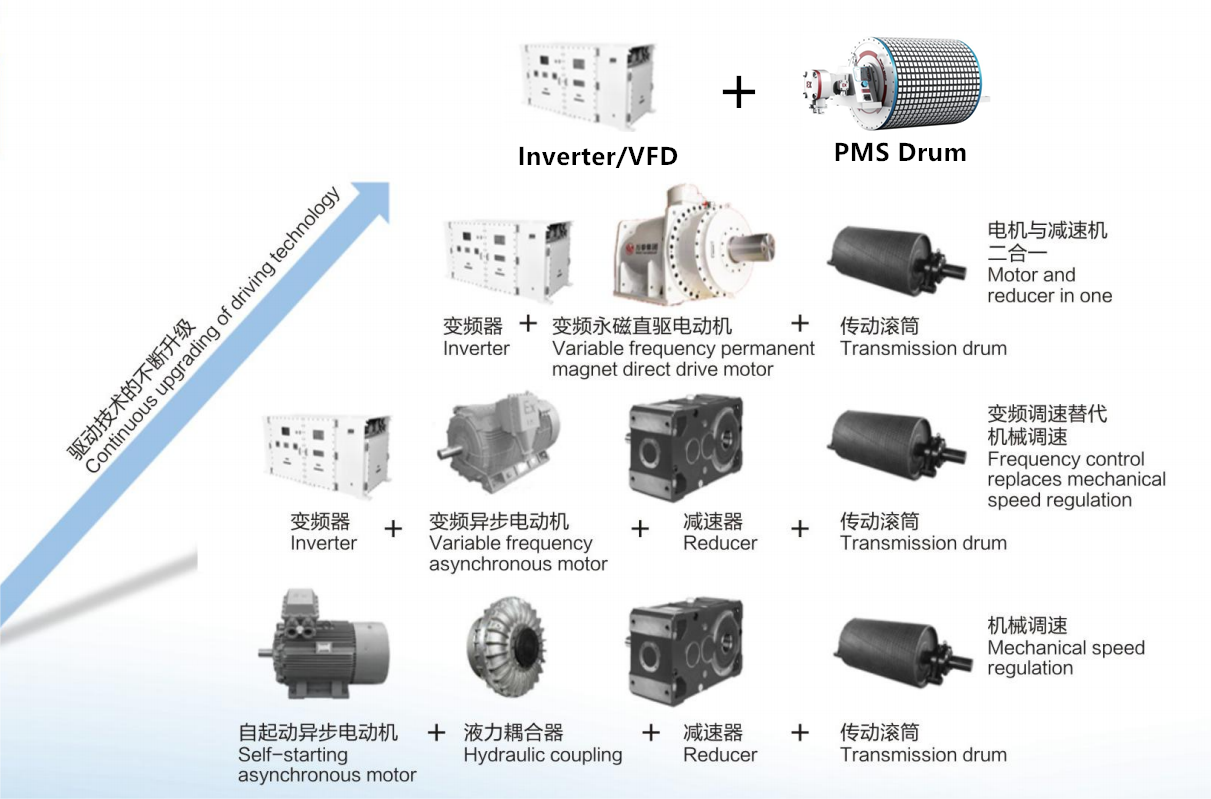

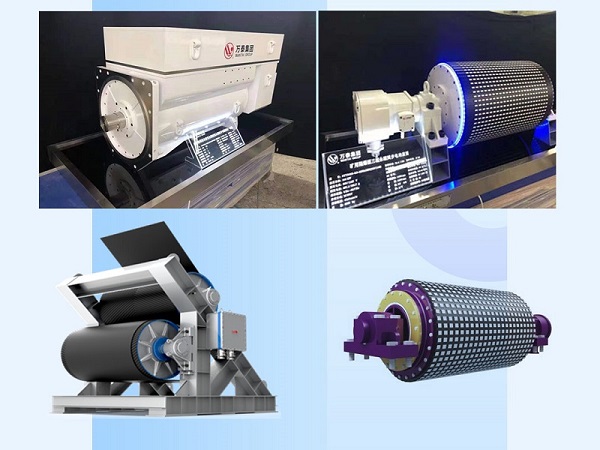

The explosion-proof three-phase permanent magnet synchronous electric drum for mining (hereinafter referred to as permanent magnet electric drum), together with the special inverter, control system, cooling device, etc., constitutes an intelligent permanent magnet outer rotor variable frequency direct drive system, which can achieve stepless speed regulation in a wide range. The permanent magnet electric drum has changed the complex transmission chain of the traditional belt conveyor composed of motor + coupler + reducer + coupling + transmission drum. The permanent magnet electric drum integrates drive, transmission and drum, bringing a revolutionary change in the belt conveyor drive system. The permanent magnet electric drum fully considers the various requirements of the equipment, inverter and control system in the speed regulation process, and is an ideal drive product for bulk material transportation machinery.

2. Product Innovation & Upgrade

Permanent magnet electric roller has changed the complex transmission chain of traditional belt conveyor, which is composed of motor + coupler + reducer + coupler + transmission roller. It integrates drive, transmission and roller, and brings a revolutionary change of belt conveyor drive system.

The permanent magnet electric drum fully considers the requirements of driven equipment, frequency converter and control system in the speed regulation process. It has the advantages of low speed, high torque, wide speed regulation range, anti frequency converter DV / dt high-frequency pulse harmonic, high efficiency and energy saving, low noise, long service life and high reliability. It is an ideal driving product for bulk material transportation machinery.

3. Technical parameters

Rated working voltage: AC 660 / 1140V

Rated output power: 55 ~ 315KW

Number of electric roller poles: 60 or 24 poles

Rated output belt speed (M / s): 2 ~ 5

Bandwidth (mm): 800 ~ 1600

Cooling mode: water cooling

Insulation grade of electric drum winding: Class H

Explosion proof type: Exd I MB

4. Technical advantages and main features

(1) High quality cladding treatment

The cladding is diversified and can be made of flame-retardant rubber, polyurethane, ceramics and other materials to meet the requirements of MT / t962-2019 cladding for coal mine belt conveyor drum

(2)Compact installation space

Integrated, permanent magnet drum = motor + hydraulic coupling + reducer + coupling + drum

(3)Energy saving and high efficiency

The mechanical transmission efficiency is 100%, with high efficiency and high power factor

(4)Reliable insulation system

VPI vacuum dipping technology is adopted, which has high electrical strength, high mechanical strength, corrosion resistance and moisture resistance. The winding adopts f / H insulation to ensure reliability

(5)Reliable bearing structure

Double row self-aligning bearing is adopted to ensure service life of more than 50000 hours

(6)Comprehensive monitoring and protection

Standard temperature measuring device, optional temperature field display table, temperature transmitter and vibration sensor to meet field requirements.

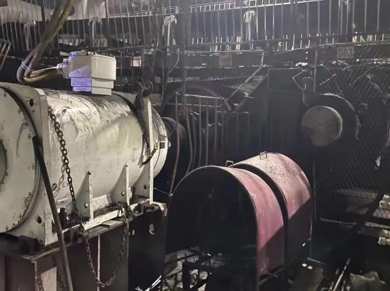

5、Manufacturing Floor

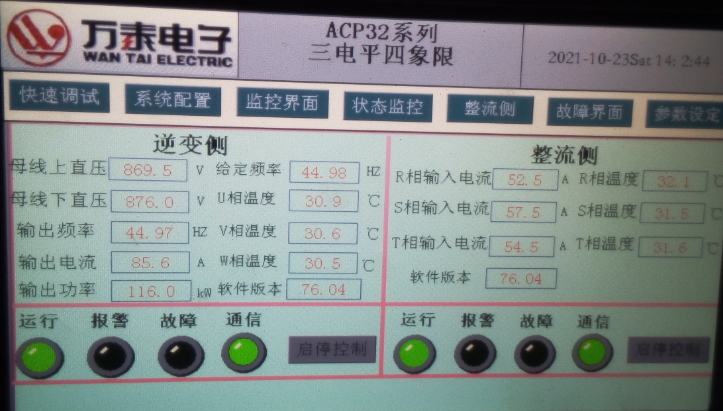

(1)The company produces its own matching frequency converters and water cooling devices.

(2)Winding machine, VPI vacuum impregnation machine.

(3)Motor loading test system, all motor products are loaded and tested before leaving the factory

6、Case

(1)Huainan Zhangji Coal Mine: 4 * 500KW permanent magnet synchronous reduction motor, transmission equipment renovation, put into trial operation in December 2021.

(2)Huainan Dingji Mine: 4 * 315KW permanent magnet drum, put into use in August 2021.

Tel : +8618355333980

Tel : +840949930668(CDCP)

Email : contact@wantaiglobal.com

Address : Intersection of Guohuai Road and Chunshen Street, Shannan New District, Huainan City, Anhui province, China