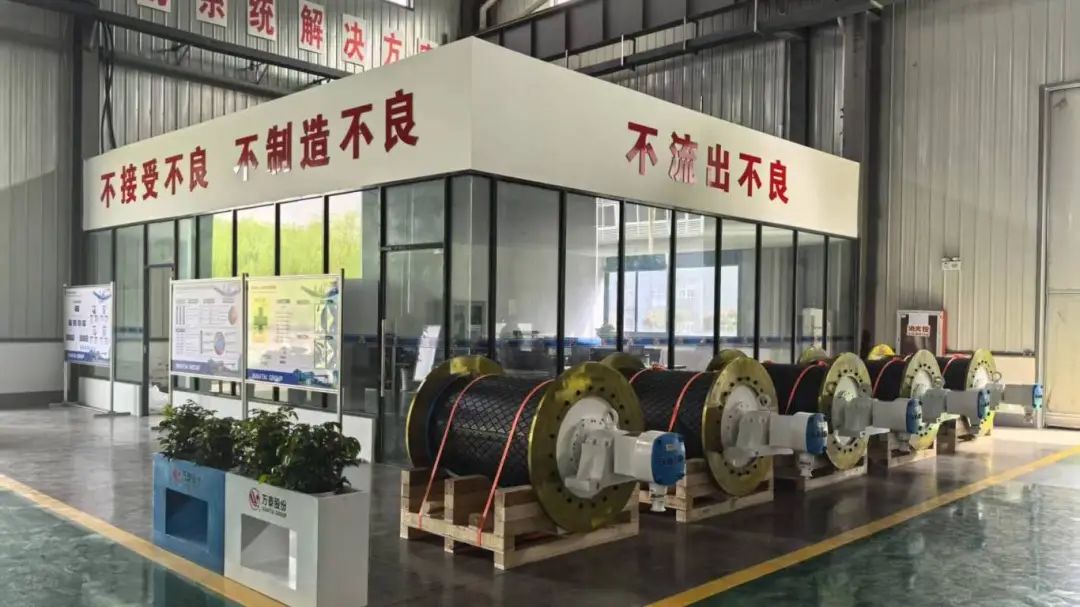

On March 27, Wantai Co., Ltd. successfully completed an important task - producing and delivering 10 flameproof three-phase permanent magnet synchronous electric drums for mining for Hebei Tianze Heavy Machinery Co., Ltd. After receiving the order, our company quickly prepared materials and arranged production work, and each project was carried out in an orderly manner. All employees of the product line uphold the spirit of craftsmanship to ensure that every delivered product can meet high quality standards. With the joint efforts of all employees, the entire process from ordering, material preparation, production, performance testing to delivery was completed in just 45 days.

The permanent magnet drum uses the "magnetic slot wedge" technology for the first time. This innovative technology has significantly improved the product performance. Through loading tests, the efficiency of the permanent magnet drum has increased by 8% and the temperature rise has decreased by 30K. While the efficiency of the permanent magnet drum has been improved, the generation of harmonics has also been greatly reduced. This means that the product is more stable and efficient during operation and can provide more reliable power support for the production operations of coal mines. The application of this new technology not only provides customers with high-quality and low-cost products, but also marks that our company's permanent magnet manufacturing technology has reached a new level.

Product Introduction

The explosion-proof three-phase permanent magnet synchronous electric drum for mining (hereinafter referred to as permanent magnet electric drum), together with special frequency converter, control system, cooling device, etc., constitutes an intelligent permanent magnet outer rotor variable frequency direct drive system, which can achieve stepless speed regulation in a wide range.

The permanent magnet electric drum has changed the complex transmission chain of the traditional belt conveyor composed of motor + coupler + reducer + coupling + transmission drum. The permanent magnet electric drum integrates drive, transmission and drum, bringing a revolutionary change in the belt conveyor drive system.

The permanent magnet electric drum fully considers the various requirements of the equipment, frequency converter and control system in the speed regulation process. It has the advantages of low speed and high torque, wide speed regulation range, anti-frequency pulse harmonics of frequency converter Dv/Dt, high efficiency and energy saving, low noise, long life and high reliability. It is an ideal drive product for bulk material transportation machinery. At the same time, the permanent magnet drum can integrate the backstop and brake disc inside, and provide an integrated solution.

Features

The efficient delivery of the permanent magnet electric drum reflects Wantai's spirit of unity, cooperation, pursuit of excellence and innovation. We will continue to uphold this spirit, keep moving forward on the road of future development, and provide customers with more high-quality products and services.

Tel : +8618355333980

Tel : +840949930668(CDCP)

Email : contact@wantaiglobal.com

Address : Intersection of Guohuai Road and Chunshen Street, Shannan New District, Huainan City, Anhui province, China